Bromobutyl Rubber Market Size, Share & Industry Analysis, By Application (Tubes & Tires, Pharmaceuticals, Adhesives & Sealants, and Others), and Regional Forecast, 2026-2034

KEY MARKET INSIGHTS

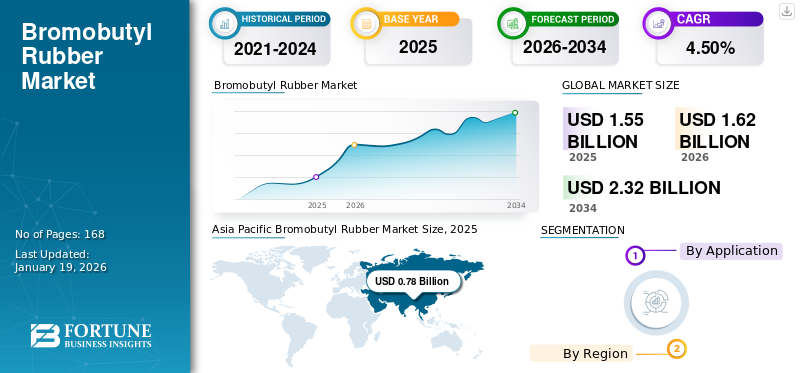

The global bromobutyl rubber market was valued at USD 1.55 billion in 2025. The market is projected to grow from USD 1.62 billion in 2026 to USD 2.32 billion by 2034, exhibiting a CAGR of 4.50% during the forecast period. Asia Pacific dominated the bromobutyl rubber market with a market share of 51% in 2025.

Bromobutyl Rubber is a synthetic elastomer produced by reacting butyl rubber with bromine. It is known for its low permeability to gases and strong resistance to heat, chemicals, and ozone. This material is commonly used in pharmaceutical packaging, automotive components, and especially in the inner linings of tubeless tires. The market is expanding steadily due to increasing demand from the automotive sector for durable and airtight materials. The pharmaceutical industry is also contributing to growth as it is ideal for applications that require high purity and protection from contamination. Rising healthcare needs and advancements in tire technology are expected to further support market expansion in the coming years.

The major manufacturers operating in the bromobutyl rubber market include Exxon Mobil Corporation, Lanxess International SA, Reliance Sibur Elastomers Private Limited, POLYPLAST, and ARLANXEO.

Market Dynamics

MARKET DRIVERS

Expansion of Healthcare and Pharmaceutical Infrastructure to Drive Product Demand

The ongoing expansion of pharmaceuticals and healthcare infrastructure is accelerating the market. With increasing access to medical services and the growing need for safe and reliable drug delivery, there is rising demand for high-quality sealing materials used in vials, syringes, and other sterile packaging. Its excellent impermeability, chemical resistance, and low gas permeability, make it a preferred material in sterile packaging. Additionally, advancements in drug formulation and the growing emphasis on contamination-free packaging are further supporting the global bromobutyl rubber market growth.

MARKET RESTRAINTS

Volatility in Raw Material Prices and Dependence on Petroleum-Based Inputs to Restrain Market Expansion

The growth of the market is restrained by its heavy dependence on petroleum-based raw materials such as isobutylene and bromine. This dependence makes production costs highly vulnerable to fluctuations in crude oil prices. Instability in global oil markets and supply chain disruptions can lead to unpredictable raw material costs, increasing overall production expenses. These rising costs impact profit margins and limit the ability of manufacturers to maintain stable pricing. As a result, fluctuating raw material prices remain a key factor restraining market growth.

MARKET OPPORTUNITIES

Growing Demand for High-Performance Tires to Support Market Expansion

The increasing demand for advanced, durable, and fuel-efficient tires is expected to offer strong growth opportunities for the market. With increasing focus on enhancing air retention, reducing rolling resistance, improving safety, and extending tire life, manufacturers are increasingly utilizing the product in tire inner liners due to its excellent air impermeability and resistance to moisture. The shift toward tubeless and radial tires further boosts the need for reliable sealing materials. Additionally, the growing replacement tire market and rising consumer preference for premium tire solutions are likely to support the use of the product in tire manufacturing in the coming years.

- According to the Observatory of Economic Complexity (OEC), in 2023, global trade of rubber tires reached USD 99 billion, ranking 29th among 1,217 products globally. This highlights strong demand for bromobutyl rubber, which is widely used in inner liners for its impermeability and air retention properties.

Bromobutyl Rubber MARKET TREND

Rise of Electric Vehicles and Advancements in Healthcare Infrastructure Reshaping Market Outlook

The growing adoption of electric vehicles (EVs) is changing tire performance requirements, with greater emphasis on air retention, durability, and low rolling resistance. Bromobutyl rubber is being increasingly used in tire inner liners to support these demands. Additionally, the healthcare sector is undergoing rapid modernization, with increased investment in injectable drug delivery systems requiring high-quality sealing materials. These applications are shaping a new trend in the market, emphasizing performance, safety, and reliability.

MARKET CHALLENGE

Environmental Regulations and Rising Use of Substitute Materials Pose a Challenge to Market Development

The market faces challenges due to the environmental impact associated with production, which depends on petroleum-based raw materials and energy-intensive processes. This has led to stricter environmental regulations across various regions, requiring manufacturers to invest heavily in cleaner and more sustainable production methods. Additionally, the increasing availability and development of alternative materials, such as bio-based and advanced synthetic elastomers, are creating competitive pressure. These factors are putting pressure on conventional production methods and limiting the adoption of products across various industries.

Download Free sample to learn more about this report.

Segmentation Analysis

By Application

Pharmaceutical Segment Dominated with Rising Demand for Contamination-Free Packaging and Drug Safety

Based on application, the market is segmented into tubes & tires, pharmaceuticals, adhesives & sealants, and others.

The pharmaceutical segment held a dominant global bromobutyl rubber market share in 2024, primarily due to the growing demand for sterile and contamination-free packaging solutions in the healthcare industry. It is widely used in the production of vial stoppers, syringe plungers, and infusion seals owing to its excellent impermeability, chemical resistance, and ability to maintain drug integrity over time. With the rise in chronic illness, rising demand for injectable drugs and vaccines, and stricter regulatory standards for drug safety, the need for high-quality packaging materials is increasing. Moreover, the expansion of pharmaceutical manufacturing in emerging markets further contributes to the rising adoption of bromobutyl rubber in this segment.

The tubes & tires segment is witnessing significant growth, driven by the material’s excellent air retention, low permeability, and high resistance to heat and flex fatigue. These properties make it ideal for use in tire inner liners and tubes, where durability and consistent performance are important. With the rise in global automotive production and the increasing preference for electric and high-performance vehicles, the demand for long-lasting and fuel-efficient tires is increasing. As a result, manufacturers are increasingly using this material to meet safety standards, further boosting the growth of the segment.

The adhesives & sealants segment is also witnessing consistent growth, driven by its excellent sealing properties, durability, and resistance to moisture and chemicals. It is widely used in construction and automotive applications for weatherproofing, glazing, and vibration-resistant joints. Rising infrastructure development and the growing need for long-lasting sealing solutions are further supporting the segment’s expansion. Additionally, its compatibility with various substrates and ease of processing make it a preferred choice among manufacturers for high-performance adhesive formulations.

Bromobutyl Rubber Market Regional Outlook

By geography, the market is categorized into Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific

Asia Pacific Bromobutyl Rubber Market Size, 2025 (USD Billion) To get more information on the regional analysis of this market, Download Free sample

The Asia Pacific region dominates USD 0.78 billion in 2025. the global bromobutyl rubber market, driven by expanding pharmaceutical and automotive industries across countries such as China, India, and Japan. The rising demand for sterile and contamination-free packaging is increasing the use of materials in pharmaceutical closures. Growing healthcare investments and the presence of major drug manufacturing companies further support the market. Additionally, rising vehicle production, infrastructure development, and urbanization are boosting the usage of tires, tubes, and sealant applications. Supportive government initiatives and cost-effective manufacturing continue to strengthen the region’s position in the global market.

North America

The market in North America is witnessing steady growth, primarily driven by the region’s well-established pharmaceutical and automotive industries. The rising demand for high-quality and contamination-free drug packaging is boosting the use of material in pharmaceutical closures. Increased healthcare spending, strict regulatory standards, and advancements in drug delivery systems are further contributing to market expansion. In the automotive industry, the push for long-lasting, high-performance tires is boosting the material’s use in inner liners and tubes. The presence of leading manufacturers in countries such as the U.S. and Canada is further boosting the material’s demand across the region.

Europe

In Europe, the market is shaped by stringent quality regulations, a strong focus on pharmaceutical safety, and rising demand for high-performance materials. It is widely used in pharmaceutical applications due to its excellent impermeability and chemical resistance, making it ideal for sterile drug packaging. Countries such as Germany, France, and the U.K. play a vital role in their advanced pharmaceutical manufacturing and innovation. The region’s well-established automotive sector is also contributing to market growth. With growing attention on sustainability, safety, and advanced material performance, the region remains a significant market for the material.

Latin America

In Latin America, the market is witnessing gradual growth, driven by the expanding pharmaceutical and automotive industries. Countries such as Brazil and Mexico are experiencing increased demand for sterile pharmaceutical packaging, driven by growing healthcare awareness, rising drug production, and improving healthcare infrastructure. Additionally, the region’s automotive sector is contributing to the use of material in tire inner liners and tubes, as demand for durable and efficient vehicles increases. Ongoing investments in healthcare and transportation are accelerating market expansion across the region.

Middle East & Africa

In the Middle East and Africa, the market is growing, driven by rising investments in healthcare, pharmaceutical manufacturing, and the automotive sector. Countries such as the UAE and Saudi Arabia are increasing their focus on improving healthcare infrastructure and expanding local drug production. Additionally, growing automotive production and efforts to diversify economies are boosting the use of material in tire and sealing applications. As the region continues to modernize its healthcare and transportation sectors, the market is expected to grow further.

COMPETITIVE LANDSCAPE

Key Industry Players

Key Companies Focus on Capacity Expansion to Maintain their Dominating Position in the Market

The global bromobutyl rubber market is highly competitive, with key players focusing on technological advancements, mergers & acquisitions, and capacity expansion to boost their market presence. Global companies include Exxon Mobil Corporation, Lanxess International SA, Reliance Sibur Elastomers Private Limited, POLYPLAST, and ARLANXEO. These companies compete based on purity levels, cost-effective processing techniques, supply chain integration, and regional dominance while investing in sustainable extraction technologies to address environmental concerns. While global leaders dominate in developed markets, regional players are expanding aggressively in emerging economies, intensifying competition in the industry.

LIST OF KEY BROMOBUTYL RUBBER COMPANIES

- Exxon Mobil Corporation (U.S.)

- Lanxess International SA (Germany)

- Nizh Yug (Nizhnekamskneftekhim) (Russia)

- Reliance Sibur Elastomers Private Limited (India)

- Hebei Xiangyi International Trading Co., Ltd. (China)

- POLYPLAST (Russia)

- YUSHENG ENTERPRISE LIMITED (China)

- ENEOS Materials Corporation (Japan)

- ARLANXEO (Netherlands)

- ELGI Rubber (India)

REPORT COVERAGE

Request for Customization to gain extensive market insights.

Report Scope & Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Estimated Year |

2026 |

|

Forecast Period |

2026-2034 |

|

Historical Period |

2021-2024 |

|

Growth Rate |

CAGR of 4.50% from 2026-2034 |

|

Unit |

Value (USD Billion) and Volume (Kiloton) |

|

Segmentation |

By Application · Tubes & Tires · Pharmaceuticals · Adhesives & Sealants · Others |

|

By Geography · North America (By Application, and By Country) o U.S. (By Application) o Canada (By Application) · Europe (By Application, and By Country) o Germany (By Application) o U.K. (By Application) o Italy (By Application) o France (By Application) o Rest of Europe (By Application) · Asia Pacific (By Application, and By Country) o China (By Application) o India (By Application) o Japan (By Application) o Southeast Asia (By Application) o Rest of Asia Pacific (By Application) · Latin America (By Application, and By Country) o Brazil (By Application) o Mexico (By Application) o Rest of Latin America (By Application) · Middle East & Africa (By Application, and By Country) o UAE (By Application) o Saudi Arabia (By Application) o Rest of Middle East & Africa (By Application) |

Frequently Asked Questions

Fortune Business Insights says that the global market value stood at USD 1.55 billion in 2025 and is projected to reach USD 2.32 billion by 2034.

In 2025, the market value stood at USD 1.55 billion.

The market is expected to exhibit a CAGR of 4.50% during the forecast period of 2026-2034.

The Key factor driving the market is the growing demand in the healthcare and pharmaceutical industry.

Exxon Mobil Corporation, Lanxess International SA, Reliance Sibur Elastomers Private Limited, POLYPLAST, and ARLANXEO are the top players in the market.

Asia Pacific dominates the market.

Rising usage of tire inner liners and the growing focus on product safety and durability in the healthcare and automotive industries are some of the key factors expected to favor product adoption.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us