Cobalt-Based Superalloys Market Size, Share & Industry Analysis, By Application (Aerospace, Power Generation, Medical Devices, Oil & Gas, and Others), and Regional Forecast, 2026-2034

KEY MARKET INSIGHTS

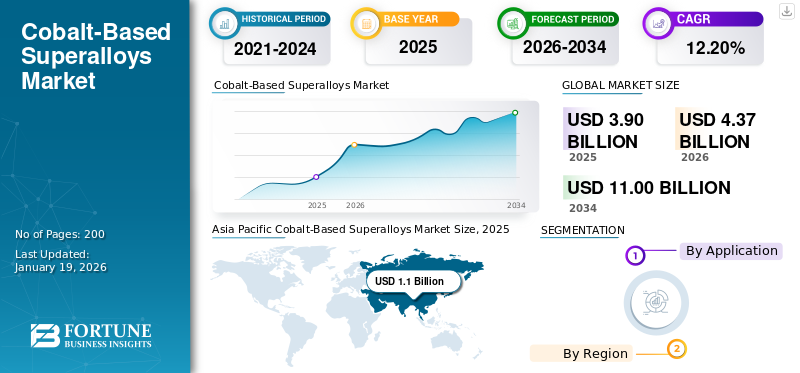

The global cobalt-based superalloys market size was valued at USD 3.9 billion in 2025. The market is projected to grow from USD 4.37 billion in 2026 to USD 11 billion by 2034, exhibiting a CAGR of 12.20% during the forecast period. Asia Pacific dominated the cobalt-based superalloys market with a market share of 29% in 2025.

Cobalt-based superalloys are high-performance materials known for their exceptional mechanical strength, corrosion resistance, and ability to retain stability at elevated temperatures. These alloys are essential in producing components for aerospace engines, gas turbines, and various industrial machinery. The market is witnessing strong growth due to the rising demand for fuel efficient aircraft and the rapid expansion of the aerospace and defense sectors. Increasing investments in advanced manufacturing technologies are also contributing to the market’s rapid growth. The need for materials that offer long-term durability in extreme conditions further boosts demand. The major manufacturers operating in the market include ATI Inc., HAYNES INTERNATIONAL, AMETEK, Inc., Aperam S.A., and American Elements.

MARKET DRIVERS

Rising Aerospace Industry Demand to Propel Market Growth

The market is experiencing strong growth, primarily driven by the expanding aerospace industry. These alloys are crucial in producing jet engines and turbine components due to their exceptional strength, high temperature resistance, and ability to perform under extreme conditions. As global air travel rises, aircraft manufacturers focus on producing more fuel efficient and durable engines. The growing demand for commercial and military aircraft is further accelerating product adoption. This ongoing growth in aerospace applications is expected to drive the global cobalt-based superalloys market growth.

MARKET RESTRAINTS

Unstable Raw Materials Costs and Supply Chain Risks to Restrain Market Growth

The market faces challenges due to unstable raw material costs and increasing supply chain risks. Cobalt, a key element in these alloys, often experiences sharp fluctuations in cost. This is due to its limited global supply, geopolitical instability, and rising demand from electric vehicles. These price variations lead to uncertain manufacturing costs and tighter profit margins for producers. The dependence on a few cobalt-producing regions further increases the risk of supply chain disruptions. As a result, this instability in both cost and availability is expected to hinder market growth over the coming years.

MARKET OPPORTUNITIES

Clean Energy Transition to Unlock Growth Opportunities for Cobalt-Based Superalloys

The ongoing transition toward clean and sustainable energy creates new opportunities for the market. As global reliance on fossil fuels declines, there is a growing focus on advanced power systems that require materials with exceptional heat resistance and durability. These superalloys are essential in applications such as high-efficiency gas turbines, nuclear reactors, and hydrogen production units. They offer the performance needed to withstand extreme temperatures and demanding environments. Increasing investments in renewables, energy storage, and modernized power infrastructure further accelerate this demand. With the ongoing focus on sustainable power generation, cobalt-based superalloys are expected to grow steadily in the coming years.

MARKET CHALLENGES

Environmental Concerns and Availability of Alternative Materials Pose Challenges to Market

The production and processing of cobalt-based superalloys involve energy-intensive methods and the use of critical raw materials, which raise environmental and sustainability concerns. The mining and refining of cobalt are often linked to ecological degradation and ethical sourcing issues. As a result, regulatory bodies are enforcing stricter environmental and supply chain standards. Meeting these regulations requires a high investment in cleaner technologies and responsible sourcing practices. Additionally, the growing development of alternative high-performance materials such as ceramic matrix composites and advanced titanium alloys is increasing competition. These materials offer similar strength and heat resistance. Their growing use increases competitive pressure on the product, pushing manufacturers to innovate and improve product efficiency.

COBALT-BASED SUPERALLOYS MARKET TRENDS

Technological Advancements in Alloy Development and High-Precision Manufacturing

The market is witnessing a growing trend driven by innovations to improve performance in high-temperature and high-stress environments. Aerospace and power generation industries are demanding alloys with enhanced strength, thermal stability, and corrosion resistance. In response, ongoing research is focused on optimizing alloy composition and refining microstructure for better reliability and efficiency. Advanced manufacturing techniques, particularly additive manufacturing (3D printing), play a key role. These technologies enable the production of complex, high-precision components with reduced material waste, improved efficiency, and enhanced durability, reinforcing the demand for advanced cobalt-based superalloys.

Download Free sample to learn more about this report.

Segmentation Analysis

By Application

Aerospace Segment Dominates with Rising Demand for High-Performance Engine Components

Based on application, the market is segmented into aerospace, power generation, medical devices, oil & gas, and others.

The aerospace segment held a dominant global cobalt-based superalloys market share in 2024, driven by the rising demand for high-performance jet engines and the increasing production of commercial and military aircraft. These superalloys are widely used in turbine blades, combustion chambers, and exhaust systems due to their superior heat resistance, strength, and fatigue life. The global focus on fuel efficiency, emission reduction, and next-generation propulsion systems is further boosting the use of these alloys in critical engine components.

In the power generation segment, the product is extensively used in gas turbines and heat exchangers. Their excellent mechanical stability at high temperatures and ability to resist oxidation and corrosion make them ideal for demanding environments in power plants. With growing investments in conventional and renewable energy infrastructure, the need for materials that can withstand extreme thermal and mechanical stress is increasing. This leads to a steady rise in the adoption of cobalt-based superalloys for power generation applications.

The medical devices segment is also a significant contributor to the market. These superalloys are used in orthopedic implants, dental prosthetics, and surgical tools due to their biocompatibility, corrosion resistance, and strength. The rising aging population globally, increasing surgical procedures, and advancements in medical implant technologies are key factors driving demand. Product offers longevity and reliability in load-bearing implants, making them ideal for joint replacements and spinal fixation devices.

Cobalt-Based Superalloys Market Regional Outlook

By geography, the market is categorized into Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific

Asia Pacific Cobalt-Based Superalloys Market Size, 2025 (USD Billion)

To get more information on the regional analysis of this market, Download Free sample

Asia Pacific dominates the global market, driven by rapid industrialization and strong demand from the aerospace, power generation, and automotive sectors. China, India, and Japan are experiencing a surge in the need for high-performance materials used in fuel-efficient aircraft engines, gas turbines, and advanced vehicle components. The rise in commercial aviation, increasing defense modernization efforts, and expanding energy infrastructure are major contributors to the growth. Moreover, ongoing investments in manufacturing technologies, the availability of raw materials, and a robust supply chain continue to support the region’s market expansion.

North America

North America is witnessing steady growth driven by the rapid advancement of aerospace, defense, power generation, and automotive industries. The U.S. and Canada play a significant role due to their strong presence of aircraft engine manufacturers, defense contractors, and energy equipment producers. These industries require high performance alloys for critical components such as jet engines, gas turbines, and missile systems. Rising investments in military modernization are supporting consistent demand. Additionally, advanced research capabilities, a well-developed industrial base, and ongoing technological innovations further strengthen the region’s position in the global market.

Europe

Europe’s market is driven by advancements in aerospace technology, energy transition efforts, and a strong focus on sustainability. Germany, France, and the U.K. have a long-established presence in aircraft engine manufacturing, gas turbine production, and high-performance automotive engineering. The demand for lightweight, durable, and heat-resistant materials continues to grow. The region is also witnessing increased investment in renewable and nuclear energy, which further supports the use of superalloys in high-temperature applications. With a well-established industrial base and a focus on innovative technologies, Europe remains a key market for the product.

Latin America

In Latin America, the market is witnessing gradual growth driven by the expansion of aerospace, energy, and industrial manufacturing sectors. Brazil and Mexico play a key role due to rising investments in aviation maintenance, defense modernization, and power infrastructure. The region is also experiencing growth in oil and gas projects, which further supports market demand. With ongoing industrial development and a shift toward advanced manufacturing, the region is becoming an emerging market for the product.

Middle East & Africa

In the Middle East & Africa, the market is expanding due to rising investments in aerospace, power generation, and industrial manufacturing. The UAE, Saudi Arabia, and South Africa drive demand through aviation growth, defense projects, and energy infrastructure. The need for heat-resistant and high-strength materials in turbines and engines is increasing. With a focus on infrastructure development and technological advancements, the region is emerging as a growing market for the product.

COMPETITIVE LANDSCAPE

Key Industry Players

Key Players are Adopting Various Business Expansion Strategies to Maintain their Market Positions

ATI Inc., HAYNES INTERNATIONAL, AMETEK, Inc., Aperam S.A., and American Elements are a few key players in the market. These players mainly operate based on the product's pricing and application features. Companies are entering into partnerships to enhance product portfolios, increase their market share, and gain a competitive edge.

LIST OF KEY COBALT-BASED SUPERALLOYS COMPANIES

- ATI Inc. (U.S.)

- HAYNES INTERNATIONAL (U.S.)

- ROLLED ALLOYS INC. (U.S.)

- AMETEK, Inc. (U.S.)

- VDM Metals (Germany)

- Aperam S.A. (Luxembourg)

- Special Metals Corporation (U.S.)

- American Elements. (U.S.)

- Höganäs AB (Sweden)

- Doncasters Group (U.K.)

REPORT COVERAGE

The market analysis provides market size & forecast for all the segments included in the report. It includes details on the market dynamics and trends expected to drive the market in the forecast period. It offers information on key regions/countries, key industry developments, new product launches, details on partnerships, and mergers & acquisitions. The report covers a detailed competitive landscape with information on the market share and profiles of key players.

Request for Customization to gain extensive market insights.

Report Scope & Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Estimated Year |

2026 |

|

Forecast Period |

2026-2034 |

|

Historical Period |

2021-2024 |

|

Growth Rate |

CAGR of 12.20% from 2026-2034 |

|

Unit |

Value (USD Billion) and Volume (Kiloton) |

|

Segmentation |

By Application

|

|

By Geography

|

Frequently Asked Questions

Fortune Business Insights says that the global market value stood at USD 3.9 billion in 2025 and is projected to reach USD 11 billion by 2034.

In 2025, the market value stood at USD 3.9 billion.

The market is expected to exhibit a CAGR of 12.20% during the forecast period of 2026-2034.

The key factors driving the cobalt-based superalloys market are the increasing demand for fuel-efficient and durable aircraft engines and advancements in military components.

ATI Inc., HAYNES INTERNATIONAL, AMETEK, Inc., Aperam S.A., and American Elements are the top players in the market.

Asia Pacific dominated the market with a share of 29% in 2025.

Growing demand for high-performance materials in aerospace and power generation, advancements in alloy technology, and increased investments in defense and energy infrastructure favor product adoption.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us