Punching Machine Market Size, Share & Industry Analysis, By Machine Type (CNC, Hydraulic, Mechanical, Electric, and Pneumatic), By Material Type (Metal, Plastic, Wood, and Others), By Mode of Operation (Automatic and Semi-automatic), By End User (Automotive, Electronics, Construction, Aerospace & Defense, and Others), and Regional Forecast, 2026 – 2034

KEY MARKET INSIGHTS

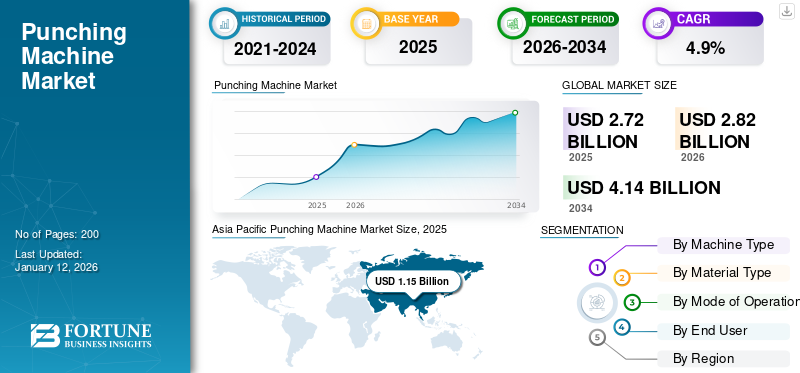

The global punching machine market size was valued at USD 2.72 billion in 2025 and is projected to grow from USD 2.82 billion in 2026 to USD 4.14 billion by 2034, exhibiting a CAGR of 4.9% during the forecast period. Asia Pacific dominated the global market with a share of 42.2% in 2025.

A punching machine is a special type of equipment used to create holes in various materials, such as plastic, paper, and metal. It uses mechanisms such as CNC, hydraulic, mechanical, and pneumatic. These types of machines are widely used in various sectors, such as automotive, electronics, construction, and aerospace & defense.

An increasing adoption of electric vehicles, industrial automation across several industries, such as the automotive, construction, and aerospace sectors, enhances the demand for precision machines, thereby fueling the market’s growth. In addition, growth in the construction and automotive sectors is boosting the demand for such machines for molding and making holes in various metal or plastic parts used in these industries. This factor is projected to drive the growth of the market. For instance, according to Autovista Group, automotive sales in Germany increased by 6.1% in 2024 as compared to 2023. Key players such as Trumph, Amada, Murata Manufacturing etc. are focusing on new product launches, partnerships, mergers, and acquisitions of businesses that offer precise product offerings as part of their growth plan to extend their business and geographical footprint. They are adopting various business strategies to tackle the supply-demand gap in the market.

Download Free sample to learn more about this report.

Global Punching Machine Market Overview

Market Size:

- 2025 Value: USD 2.72 billion

- 2026 Estimate: USD 2.82 billion

- 2034 Forecast Value: USD 4.14 billion

- CAGR:4.9% from 2026 to 2034

Market Share:

- Regional Leader: Asia Pacific accounted for the largest market share in 2024, driven by robust industrialization and manufacturing.

- Machine Type Leader: CNC punching machines led by segment revenue, boosted by Industry 4.0 adoption and demand for precision.

- Material Type Leader: Metal punching dominated the market due to extensive use in automotive, electronics, and construction sectors.

- Mode of Operation Leader: Automatic punching machines captured the largest share, increasingly preferred over semi‑automatic systems.

- End‑User Leader: The automotive industry was the leading end-user in 2024, fueled by demand for precision metal components.

Industry Trends:

- Rising integration of Industry 4.0 technologies in punching machines, including CAD/CAM integration, predictive maintenance, and real-time monitoring.

- Increasing use of lightweight and advanced materials in automobiles and electronics driving demand for high‑precision punching solutions.

- Growth of servo-driven and electric punching technologies alongside CNC as leading systems for efficiency and environmental compliance.

Driving Factors:

- Demand for high-precision metal and plastic fabrications across automotive, construction, aerospace, and electronics sectors.

- Expansion of global infrastructure and e‑mobility trends boosting adoption of advanced punching technologies.

- Post-pandemic shift to automated CNC machines to reduce labor dependency and increase consistency and throughput.

- Infrastructure investments and rising demand for customizable manufacturing in Asia, North America, and Europe.

The COVID-19 pandemic had a mixed impact on the global punching machine market share owing to halted manufacturing activities in the aerospace, automotive, and construction industries and a decrease in investment in manufacturing facilities. This factor reduced the demand for punching machines. However, post-pandemic, the adoption of CNC or automated punching machines increased owing to reduced dependence on manual labor, which fueled the growth of the market.

IMPACT OF TECHNOLOGY

Integration of Industry 4.0 and Smart Technology to Fuel Market Growth

The penetration of Industry 4.0 and the integration of smart technologies in various industries, including automotive, construction, and aerospace, is increasing. These technologies enable real-time monitoring, predictive maintenance, and remote operations, which are expected to drive the market’s growth. In addition, seamless integration with 3D simulation technology and CAD and CAM systems enhances precision and improves production capacity in various industries, driving the growth of the market.

IMPACT OF TARIFFS ON THE MARKET

Supply Chain Disruption and Increased Raw Material Costs to Limit Market Growth

Owing to increased raw materials and enhanced operational costs, the punching machine market is projected to witness steady or slowed growth. Tariffs imposed by the U.S. government disrupt the supply chain, resulting in delayed production processes and operational complexities. Manufacturers, due to increased production costs, reduce the margins for distributors and suppliers, making it even more costly for end users.

Punching Machine Market Trends

Growth of Lightweight and Advanced Materials to Fuel Market Progress

The increasing adoption of lightweight and advanced materials in passenger vehicles and electric cars increases the demand for such machines to fabricate precision components. In addition, the rising use of lightweight and biocompatible materials in various industrial sectors, such as electronics, construction, medical, and aerospace, is expected to fuel the market’s growth. Moreover, growth in the aerospace sector creates demand for these machines, which is likely to boost the market’s growth. For instance, according to the Redline Group, the global aerospace market is projected to record a CAGR of 7% between 2024 and 2025.

MARKET DYNAMICS

Market Drivers

Rising Demand for Precision Manufacturing to Drive Market Growth

Rising demand for precision manufacturing in various industries, such as automotive, aerospace, construction, and electronics, has enhanced the demand for punching machines for making holes in plastic and metal components. This factor is anticipated to drive the growth of the market. Precision manufacturing has features such as accuracy, consistency, and reduced material wastage. Moreover, rapid urbanization, particularly in China and India, has fueled the demand for plastic and metal components in industries such as automotive, construction, and aerospace, thereby enhancing the demand for these machines and driving the growth of the market. For instance, according to Reuters, China's urbanization rate is projected to reach 70% in the next five years, from 2024 to 2030.

Market Restraints

High Capital Investment Costs to Restrict Market Growth

Technologically advanced punching machines, including CNC machines that are integrated with smart sensors and cutting-edge technologies, entail a considerable initial investment, leading to higher expenses. They incur additional operational costs, which can restrict the market’s growth. For example, the price of a punching machine falls between USD 10,000 and USD 50,000 and fluctuates depending on the size of the business.

Market Opportunities

Rising Infrastructure Investment Across Industries to Provide Opportunity for Market Growth

Rising investments in infrastructure across Africa, South America, and the Middle East & Africa are projected to further drive the demand for punching machines that produce metal and plastic goods used in a variety of industrial sectors. As per industry experts, the global demand for infrastructure investment is projected to reach USD 94 trillion by 2040.

SEGMENTATION ANALYSIS

By Machine Type

CNC Machine Dominates Market Owing to Increasing Adoption of Industry 4.0 Practices

Based on machine type, the market is classified into CNC, hydraulic, mechanical, electric, and pneumatic.

The CNC segment dominates the market and is projected to experience moderate growth during the forecast period. This growth is driven by factors such as the increasing adoption of Industry 4.0 practices and rising demand for smart manufacturing solutions.

The hydraulic segment is expected to experience steady growth during the forecast period, driven by the increasing utilization of hydraulic punching machines across various sectors, including construction, automotive, and shipbuilding. The segment held 24% of the market share in 2024.

The mechanical segment is expected to experience moderate growth during the forecast period. This growth can be attributed to several factors, including the simple design of these punching machines, their robust construction, and their suitability for high-speed production.

The electric segment is expected to experience moderate growth during the forecast period. This growth is attributed to the widespread use of these machines in industrial processes, such as sheet metal punching, perforation, and embossing, in various sectors, including automotive, aerospace, construction, and furniture.

The pneumatic punching machine is projected to grow at a decent rate during the forecast period owing to benefits associated with these systems, such as cost-effectiveness, high efficiency, and low maintenance requirements. In addition, the rising adoption of such machines in the automotive, construction, and consumer electronics sectors is anticipated to drive the growth of the segment.

To know how our report can help streamline your business, Speak to Analyst

By Material Type

Metal Segment Dominated Market Owing to its Lucrative Benefits

Based on material type, the market is classified into metal, plastic, wood, and others.

The metal segment dominated the market in terms of revenue in 2026. This is attributed to the widespread use of metal in punching applications and its strength and versatility. Additionally, the growing utilization of metal across various industries, including automotive and construction, is driving the segment growth. This segment is exhibited to project a CAGR of 72.34% during the forecast period.

The plastic segment is expected to grow steadily during the forecast period due to the increasing adoption of thermoplastic and thermosetting plastics across various industries, including automotive and electronics. This trend is driving the demand for machines that can punch holes in plastic materials, thereby fueling the segment growth. The segment is expected to hold 13% of the market share in 2025.

The wood segment is expected to experience moderate growth during the forecast period as these machines are gaining popularity in sectors such as furniture, construction, interior design, and woodworking. Additionally, the expansion of construction activities and the thriving furniture industry are driving the growth of the segment.

The others segment includes foam and similar materials. This segment is projected to experience a steady growth rate during the forecast period, driven by the characteristics of these materials, such as lightweight properties, compressibility, and high density. Furthermore, these machines find applications in various sectors, including automotive, furniture, packaging, and medical equipment, all of which will contribute to the segment growth.

By Mode of Operation

Increasing Use of Fully Automatic Machines to Drive Segment Growth

Based on mode of operation, the market is segmented into automatic and semi-automatic.

The automatic segment is expected to exhibit a CAGR of 69.50% throughout the forecast period. This growth is attributed to the increasing use of fully automatic machines that require no human intervention, the use of CNC controls, and their high production capacity in various industries, including automotive and metalworking.

The semi-automatic segment is expected to experience steady growth during the forecast period, driven by factors such as their cost-effectiveness, which makes them suitable for both small and medium-sized enterprises. These machines are commonly utilized in prototyping and artisan industries, which will also contribute to the growth of this segment. The segment is likely to acquire 31% of the market share in 2025.

By End User

Automotive Sector Dominated Market Owing to Rising Adoption of Products in Sheet Metal Forming and Assembly Lines

Based on end-user, the market is segmented into automotive, electronics, construction, aerospace & defense, and others.

The automotive segment led the market in terms of revenue share in 2024 and is projected to experience the highest growth rate during the forecast period. These machines are employed for tasks such as shaping sheet metal, producing precision components, manufacturing interior parts, and processing lightweight materials. This factor is projected to contribute to the segment’s growth.

The electronics segment is expected to experience steady CAGR of 5.40% during the forecast period, driven by factors such as the increasing demand for smartphones and other electronic devices. This surge in demand is anticipated to propel the need for high-quality precision metal stamping and punching machines, thereby stimulating the segment’s growth.

The construction and aerospace & defense segments are expected to steadily grow during the forecast period. This growth is driven by increased investment in construction-related activities and a rising demand for machinery used in the aerospace and defense industries. The aerospace & defense segment is likely to hold 18% of the market share in 2025.

The others segment includes agriculture and furniture. The manufacturing of tractors, harvesters, and irrigation systems necessitates the use of punched metal components, thereby driving the product’s demand in these industries.

PUNCHING MACHINE MARKET REGIONAL OUTLOOK

The punching machine market regional report covers five major regions, mainly North America, Europe, Asia Pacific, the Middle East & Africa, and South America.

Asia Pacific

Asia Pacific Punching Machine Market Size, 2025 (USD Billion)

To get more information on the regional analysis of this market, Download Free sample

Asia Pacific dominated the market in terms of revenue share in 2024. This region is projected to experience the highest growth due to factors such as rapid urbanization and increasing government investment in construction-related activities. Furthermore, the increasing adoption of CNC and automated machines owing to their features, such as high precision and capability to handle complex tasks, will further fuel the market’s growth. The regional market value in 2026 was USD 1.20 billion, and in 2025, the market value led the region by USD 1.15 billion.

China to Dominate Market Owing to Rising Adoption in Multiple Industries

China is a global manufacturer that uses punching machines extensively across various sectors, such as automotive, construction, and electronics. Moreover, rising government investment in the country’s infrastructure and the automotive sector will enhance the demand for these machines. For instance, according to the China Association of Automobile Manufacturers (CAAM), the net car sales volume in China increased by 11.6% between 2022 and 2023. The China’s market size is anticipated to hit USD 0.48 billion in 2026. On the other hand, the Japan is likely to stand at USD 0.22 billion and Indian market value is expected to be USD 0.16 billion in 2026.

To know how our report can help streamline your business, Speak to Analyst

North America

The North American market is projected to experience moderate growth due to the robust presence of the automotive, electronics, and aerospace industries. This will enhance the demand for these machines. The growing adoption of Industry 4.0 technologies, particularly CNC punching machines equipped with advanced features, such as IoT connectivity and real-time monitoring in various sectors, including automotive and electronics, is a key driver of the market’s growth in the region. North America region is to be anticipated as the third-largest market with USD 0.58 billion in 2026.

The U.S. market’s growth is shaped by factors such as a robust manufacturing base and the growing adoption of Industry 4.0 practices within the manufacturing and fabrication sectors. Additionally, rising investments in the construction and electronics sectors will boost the demand for machines for drilling holes and producing metal blanks. This will further stimulate the market’s growth in the region. The U.S. market size is likely to be USD 0.44 billion in 2026.

Europe

Europe is anticipated to account for the second-highest market size of USD 0.73 billion in 2026, exhibiting the second-fastest growing CAGR of 4.47% during the forecast period. Europe is expected to experience steady growth during the forecast period, driven by factors such as expansion of the automotive sector and increasing government investment in infrastructure-related activities. These factors will enhance the demand for punching machines in the region. For example, according to Germany Trade & Invest (GTAI), the automotive sector is projected to account for approximately 24% of Germany's total GDP in 2024. This significant contribution from the automotive sector is a key driver of the regional market’s growth. The market value in U.K. is expected to be USD 0.10 billion in 2026.

On the other hand, Germany is projecting to hit USD 0.19 billion and France is likely to hold USD 0.12 billion in 2025.

Middle East & Africa

The Middle East & Africa region is to be anticipated as the fourth-largest market with USD 0.19 billion in 2026. The Middle East & Africa is projected to experience moderate growth throughout the forecast period, driven by factors such as an increase in construction and infrastructure activities and expansion of the aerospace and defense industries in Israel and Saudi Arabia. This growth is expected to generate demand for punching machines in the region. The GCC market size is expected to hit USD 0.12 billion in 2025.

South America

South America is anticipated to experience significant growth, driven by increased investment in the automotive industry and a rising demand for fabrication services in the furniture and automotive sectors. This will enhance the need for machines used in blanking and stamping applications, further propelling the market’s growth in the region.

COMPETITIVE LANDSCAPE

KEY INDUSTRY PLAYERS

Major Players to Focus on Product Development, Launch, and Acquisitions to Intensify Market Competition

Key players, such as Trumpf Group, AMADA CO. Ltd, Prima Power, Danobat Group, and others, are engaged in product launches, product development processes, and acquisitions to strengthen the market competition. For instance, in October 2023, Trumpf Group launched a new automatic TruMatic 5000 sheet master at Blechexpo held at Stuttgart, Germany. This machine is fully automatic and can handle laser cutting, forming, and punching applications. It operates in electric mode, which consumes 30% less energy. These factors will drive the punching machine market growth.

Long List of Companies Studied (including but not limited to)

- Trumpf Group (Germany)

- AMADA Co. Ltd (Japan)

- Prima Power (Italy)

- Bystronic Group (Switzerland)

- Salvagnini Group (Italy)

- Murata Machinery Co. Ltd (Japan)

- Danobat Group (Spain)

- MAZAK Corporation (Japan)

- LVD Group (Belgium)

- Haco Group (Switzerland)

- Nisshinbo Mechatronics Inc (Japan)

- Dallan S.p.A. (Italy)

- Boschert GmbH & Co. KG (Germany)

- Finn-Power OY (Finland)

- Lagun Engineering (U.S.)

- Geka Group (Spain)

- Yangli Group (China)

- HARSLE (China)

- JDM Jingda Machine (Ningbo) Co., Ltd. (China)

KEY INDUSTRY DEVELOPMENTS

- September 2024: Prima Power introduced the Shear Genius 1530 EVO, a machine tailored for making holes in square components or cardboard sheets. It boasts advantages, such as cost-effectiveness and increased productivity. This machine can execute a variety of tasks, including punching, forming, marking, and shearing.

- January 2024: Trumpf India, part of the Trumpf Group, introduced the TruLaser series 1000 punch machine for the automotive and manufacturing industries. This machine includes several features, such as high durability, integration with Industry 4.0 solutions, and the ability to connect effortlessly with other machines.

- June 2023: Murata Machinery USA, a subsidiary of Murata Machinery Co. Ltd., introduced a new M3048/58TG laser and cutting machine capable of moving materials among various machines. This machine boasts numerous features, including rapid operation, precision, and the use of advanced technology. It enhances efficiency and boosts the productivity of manufacturing processes.

- August 2022: Olson Electronics entered into a partnership with Trumpf Group to supply Power Distribution Units (PDUs) for the TruePunch 1000 CNC punching machine. The primary goal of this collaboration was to ensure a power backup system for the punching machines. These machines are utilized across multiple industries, including medical and automotive. The punching capacity of this machine is 600 holes every minute.

- January 2022: Bystronic Group acquired Antil S.p.A., located in Milan, Italy, which specializes in automation solutions for laser cutting equipment. The objective of this acquisition was to enhance competition within the market.

REPORT COVERAGE

The report provides a detailed analysis of the market and focuses on key aspects such as leading companies, machine types, material types, mode of operations, and end users. Besides, it offers insights into the market trends and highlights key industry developments. In addition to the factors above, it encompasses several factors that contributed to the growth of the market in recent years.

Request for Customization to gain extensive market insights.

REPORT SCOPE & SEGMENTATION

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Forecast Period |

2026-2034 |

|

Historical Period |

2021-2023 |

|

Growth Rate |

CAGR of 4.9% from 2026 to 2034 |

|

Unit |

Value (USD Million) |

|

Segmentation |

By Machine Type, Material Type, Mode of Operation, End User, and Region |

|

Segmentation |

By Machine Type

By Material Type

By Mode of Operation

By End User

By Region

|

|

Companies Profiled in the Report |

Trumpf Group (Germany), AMADA Co. Ltd (Japan), Prima Power (Italy), Bystronic Group (Switzerland), Salvagini Group (Italy), Murata Machinery Co. Ltd (Japan), Danobat Group (Spain), MAZAK Corporation (Japan), LVD Group (Belgium), and Haco Group (Switzerland). |

Frequently Asked Questions

As per a Fortune Business Insights study, the market was valued at USD 2.82 billion in 2026.

The market is expected to record a valuation of USD 4.14 billion by 2034.

The market is projected to record a CAGR of 4.9% during the forecast period of 2026-2034.

By machine type, the CNC segment is expected to lead the market over the forecast period.

Rising demand for precision manufacturing is expected to drive the market’s growth.

Trumpf Group, AMADA Co. Ltd, Prima Power, Bystronic Group, Salvagini Group, Murata Machinery Co. Ltd, Danobat Group, MAZAK Corporation, LVD Group, and Haco Group are the leading companies in this market.

Asia Pacific is anticipated to be the largest shareholder of the market during the forecast period.

Growth of lightweight and advanced materials is the key trend.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us