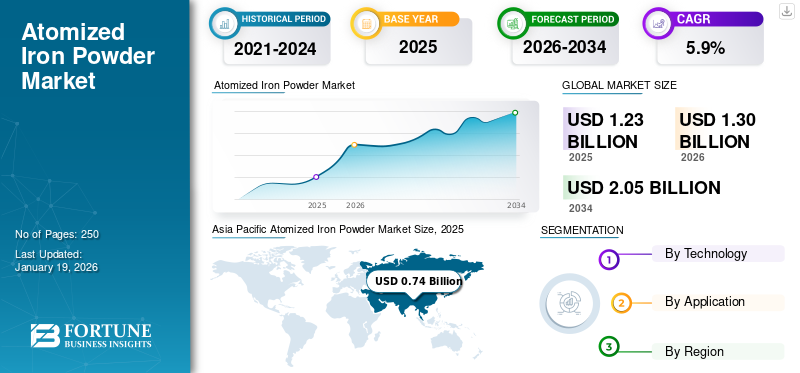

Atomized Iron Powder Market Size, Share & Industry Analysis, By Technology (Water Atomization and Gas Atomization), By Application (Powder Metallurgy, Chemical Synthesis, Electronic Materials, Pharmaceutical, and Others), and Regional Forecast, 2026-2034

KEY MARKET INSIGHTS

The global atomized iron powder market size was valued at USD 1.23 billion in 2025 and is projected to grow from USD 1.3 billion in 2026 to USD 2.05 billion by 2034, exhibiting a CAGR of 5.9% during the forecast period. Asia Pacific dominated the atomized iron powder market with a market share of 60% in 2025.

Atomized iron powder plays a vital role in the powder metallurgy industry, and it is used as a high-quality material in industries such as automotive, aerospace, and manufacturing. It is a finely powdered form of iron that is produced by a process known as atomization, where molten iron is rapidly cooled and fragmented into tiny particles using high-pressure gas or water spray. The unique properties of atomized powder, such as its high density and excellent flow ability, make it suitable for powder metallurgy processes, allowing for making parts with complex shapes and high precision. Rising demand from the automotive industry, aerospace industry, and chemical industry will significantly drive the market growth.

The main players working in the market include Rio Tinto, GKN Powder Metallurgy, Höganäs AB, JFE Steel Corporation, and INDUSTRIAL METAL POWDERS INDIA PVT.LTD.

ATOMIZED IRON POWDER MARKET TRENDS

Increase in Environmental Sustainability and Recycling Initiatives Led to Market Growth

Environmental concerns and strict regulations are pushing manufacturers toward sustainable practices. The product supports sustainability by enabling energy-efficient production methods and recycling scrap metal into usable powder. Its application in powder metallurgy also reduces energy consumption compared to traditional forging or machining. Several companies are now investing in greener technologies for atomization and adopting ecological economy principles.

MARKET DYNAMICS

MARKET DRIVERS

Increasing Advancements in Additive Manufacturing Technologies Fueling Market Growth

The rapid advancements in additive manufacturing, also known as 3D printing, are another significant driver for the growth of the atomized iron powder sector. Additive manufacturing creates complex and customized parts directly from digital models without the need for traditional molds or tooling. As additive manufacturing technologies become more refined and accessible, industries such as aerospace, medical, and electronics are increasingly adopting 3D printing techniques for prototyping and production. The product plays a vital role in this process, especially in metal 3D printing, as it creates high-strength metal components with high precision. Hence, increasing product demand from additive manufacturing is expected to drive the atomized iron powder market growth.

MARKET RESTRAINTS

Cost and Production Complexity of Product Restrain Market Growth

The production of atomized iron powder is relatively more expensive and complex compared to other forms of iron or metal powders. Atomization involves melting iron at high temperatures and rapidly cooling it using high-pressure gases or water jets. This process demands sophisticated equipment, significant energy input, and highly controlled conditions. This increases the overall production cost of atomized iron powder. As a result, the high costs associated with production can limit its widespread use.

MARKET OPPORTUNITIES

Increasing Technological Advancements in Magnetic Materials are a Major Opportunity for Market

The growing demand for advanced magnetic materials presents an opportunity for the market. Iron-based magnetic materials are important in numerous applications, such as electric motors, transformers, sensors, and data storage devices. The use of the product in producing soft magnetic materials, such as iron alloys, allows for greater precision and efficiency in manufacturing. As industries continue to innovate, particularly in fields such as renewable energy, electronics, and telecommunications, the need for high-performance magnetic materials is expected to increase.

- As per the International Energy Agency report, by 2030, global renewable electricity generation will increase by 17,000 TWh, 90% more than in 2023, and the production will be enough to meet the demand of China and the U.S. by 2030. This growth will increase demand for the atomized iron powder industry, as it is an important raw material for magnetic materials production.

MARKET CHALLENGES

Market Competition and Price Pressure are Major Challenges to Market

Intense market competition and price pressure are significant challenges for players. The increasing demand for atomized-based iron powder across various industries, including automotive, medical, and electronics, has attracted many competitors, both established manufacturers and new entrants. This has created high competition where companies are under constant pressure to offer high-quality products at competitive prices.

TRADE PROTECTIONISM

Trade protectionism has become a major issue impacting the global market. For example, the U.S. has imposed anti-dumping tariffs on Chinese metal powders, aiming to protect local production. These tariffs have made imported powders costlier, influencing the competitiveness of foreign suppliers. While such protective policies aim to safeguard local industries, they can also drive up prices and create challenges for manufacturers who rely on imported raw materials. Moreover, geopolitical tensions and trade wars can disrupt the smooth flow of materials and goods, leading to volatility in the market.

Download Free sample to learn more about this report.

Segmentation Analysis

By Technology

Water Atomization Technology Leads Market as It is Easy to Use and Affordable

Based on technology, the market is classified into water atomization and gas atomization.

The water atomization segment holds the highest atomized iron powder market share. In the water atomization process, molten metal is exposed to a high-pressure stream of water, which causes the metal to break into fine particles that quickly solidify into powder particles. The water atomization method is popular as it is cost-effective and simple. It produces powders with an equal particle size distribution, making it suitable for various applications.

Gas atomization technology is one of the most widely used technologies. In this process, molten metal is injected into a high-velocity stream of gas, typically nitrogen or argon, which atomizes the metal into fine droplets. These droplets solidify into spherical powder particles with highly controlled size and distribution. Gas atomization produces powders with superior quality, purity, and ability to flow, making it ideal for applications that require high-performance materials, such as in the aerospace and electronics industries.

By Application

Powder Metallurgy Segment Dominates Market due to Its Widespread Use in Automotive and Electrical Industries

Based on application, the market is classified into powder metallurgy, chemical synthesis, electronic materials, pharmaceutical, and others.

In the powder metallurgy industry, atomized iron powder is critical as a key raw material for producing high-performance parts and components. This industry influences the unique properties of iron powder, such as its uniform particle size and excellent ability to flow, to create sintered parts with complex shapes and high precision. It is used in manufacturing automotive parts such as gears, bearings, and structural components, as well as tools and industrial machinery. The powder metallurgy process allows for the efficient production of parts with minimal waste, reducing material costs and enhancing manufacturing process efficiency.

In the chemical synthesis, the product is utilized as a catalyst in processes and as a reducing agent. Due to its high surface area and reactivity, the product is used to produce catalysts that facilitate various chemical reactions, including hydrogenation, dehydrogenation, and oxidation reactions. Additionally, it serves as a powerful reducing agent in manufacturing chemicals such as titanium dioxide and in environmental applications, such as water treatment processes.

The electronics industry also benefits from the use of atomized-based iron powder in the production of electronic materials such as magnetic alloys and components. The product is particularly valued for its magnetic properties, essential in creating efficient and high-performance magnetic materials used in electric motors, sensors, and other electronic devices. In addition to magnetic applications, the product is also used in producing various electronic parts through powder metallurgy techniques.

Atomized Iron Powder Market Regional Outlook

By region, the market is categorized into Asia Pacific, North America, Europe, Latin America, and Middle East & Africa.

Asia Pacific

Asia Pacific Atomized Iron Powder Market Size, 2025 (USD Billion)

To get more information on the regional analysis of this market, Download Free sample

Asia Pacific is projected to witness the highest growth rate in the market with market size of USD 0.74 billion in 2025, fueled by the increasing manufacturing sectors in countries such as China, India, and Japan. The region’s booming automotive, electronics, and construction industries are major consumers of atomized powder, which is essential for producing parts that require high precision and strength. Additionally, the Asia Pacific region benefits from relatively lower production costs and the availability of abundant raw materials, making it an attractive market for both local and international manufacturers.

- As per the India Briefing article, in 2023, India’s electronics manufacturing reached USD 102 billion, supported by components and sub-assembly, and by 2030, the demand will increase by USD 240 billion.

North America

The North American market is driven by a robust industrial base, particularly in automotive, aerospace, and electronics. The region's high demand for precision-engineered components, coupled with advanced manufacturing processes, fuels the need for high-quality atomized iron powder. As industries move toward automation and smart manufacturing, the demand for advanced iron powders is expected to grow.

- As per the Observatory of Economic Complexity (OEC), in 2023, the U.S. was a top importer of cars, with an importing value of USD 208.0 billion, with a market share of 21.4%.

Europe

Europe is one of the important markets for atomized iron powder, driven by its strong automotive and machinery sectors. The region’s focus on high-performance and lightweight materials, especially for automotive and aerospace applications, fuels demand for advanced iron powders. Furthermore, European manufacturers are increasingly adopting sustainable practices due to strict environmental regulations, pushing for cleaner production processes.

- As per the Observatory of Economic Complexity (OEC), in 2023, Sweden was a top exporter and producer of iron powder, with an exporting value of USD 474.0 million, with a market share of 19.8%.

Latin America

Latin America's product demand is growing at a slower pace compared to other regions. Brazil and Mexico are the primary markets, with demand fueled by the automotive and construction industries.

Middle East & Africa

The Middle East & Africa region has steady consumption of the product, but is showing growth potential. The Middle East, particularly the Gulf Cooperation Council (GCC) countries, is investing heavily in infrastructure and industrial diversification, driving demand for atomized iron powder in construction and manufacturing.

- As per theInternational Trade Administration, in 2023, Mexico was the world’s seventh-largest passenger vehicle manufacturer, producing 3.5 million vehicles yearly.

COMPETITIVE LANDSCAPE

Key Industry Players

Continuous Development and Introduction of New Products by Key Companies Resulted in their Dominating Positions in Market

The market for atomized iron powder is highly competitive, with key companies concentrating on capacity growth, mergers & acquisitions, and sustainability to maintain their dominance. Rio Tinto, Höganäs AB, JFE Steel Corporation, GKN Powder Metallurgy, and Industrial Metal Powders India Pvt. Ltd are some of the major player in the market. They compete on the basis of cost-efficiency, product modernization, and regional dominance. While global leaders rule in developed markets, regional players are expanding aggressively in developing economies, escalating competition in the industry.

LIST OF KEY ATOMIZED IRON POWDER COMPANIES PROFILED

- Rio Tinto (U.K)

- GKN Powder Metallurgy (U.K)

- Höganäs AB (Sweden)

- JFE Steel Corporation (Japan)

- Hangzhou Yitong New Materials Co., Ltd. (China)

- CNPC POWDER (Canada)

- Luode Powder Metallurgy Factory (China)

- Industrial Metal Powders India Pvt. Ltd. (India)

- SLM Metal Private Limited (India)

- Porwal Metallurgicals (India)

REPORT COVERAGE

The global atomized iron powder market analysis provides market size & forecast by all the segments included in the report. It includes details on the market dynamics and market trends expected to drive the market over the forecast period. It offers information about the key regions/countries, key industry developments, new product launches, details on partnerships, mergers & acquisitions, and a number of manufacturers in key countries. The report covers a detailed competitive landscape with information on the market share and profiles of key players.

Request for Customization to gain extensive market insights.

Report Scope & Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Estimated Year |

2026 |

|

Forecast Period |

2026-2034 |

|

Historical Period |

2021-2024 |

|

Growth Rate |

CAGR of 5.9% from 2026-2034 |

|

Unit |

Value (USD Billion) Volume (Kilotons) |

|

Segmentation |

By Technology

|

|

By Application

|

|

|

By Region

|

Frequently Asked Questions

Fortune Business Insights says that the global market value stood at USD 1.3 billion in 2026 and is projected to reach USD 2.05 billion by 2034.

In 2025, the market value stood at USD 0.74 billion.

The market is expected to exhibit a CAGR of 5.9% during the forecast period of 2026-2034.

By technology, the water atomization segment leads the market.

Increasing use of additive manufacturing is boosting market expansion.

Rio Tinto, GKN Powder Metallurgy, Höganäs AB, JFE Steel Corporation, and INDUSTRIAL METAL POWDERS INDIA PVT.LTD are some of the leading players in the market.

Asia Pacific dominated the market in 2025.

The increasing use of magnetic materials in the automotive and electronics industries is expected to favor product adoption.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us