Decanter Centrifuge Market Size, Share & Industry Analysis, By Product Type (Two-phase and Three-phase), By Design Type (Vertical Decanter, Horizontal Decanter, and Conveyor Centrifuge Decanter), By Application (Mining and Minerals, Heavy Oil and Mineral Oil, Food and Beverage, Biofuels/Agriculture Processing, Water Management, Chemical, Pharmaceuticals & Biotechnology, and Others), and Regional Forecast, 2026-2034

DECANTER CENTRIFUGE MARKET SIZE AND FUTURE OUTLOOK

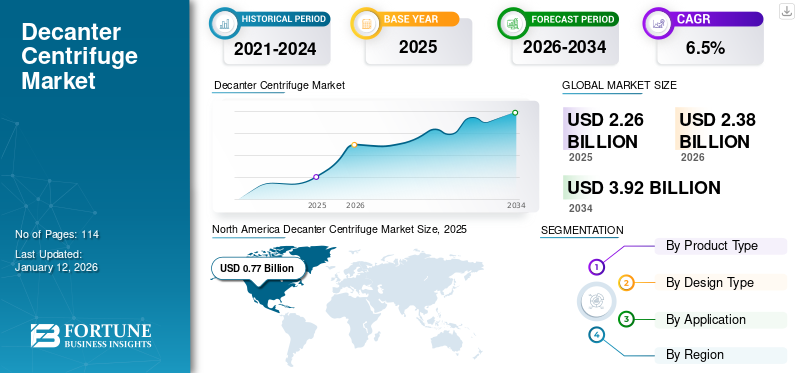

The global decanter centrifuge market size was valued at USD 2.26 billion in 2025 and is projected to grow from USD 2.38 billion in 2026 to USD 3.92 billion by 2034, exhibiting a CAGR of 6.5% during the forecast period. The North America dominated global market with a share of 34.1% in 2025.

Decanter centrifuge is also called a scroll centrifuge. It finds applications across numerous industry verticals, such as oil & gas, wastewater treatment, mineral processing, chemical processing, food & beverages, and pharmaceuticals for performing solid and liquid separation. It operates by applying centrifugal force to separate solids from liquids, making them essential for processes such as sludge dewatering and juice clarification. Players such as GEA Group Aktiengesellschaft, IHI Corporation, Flottweg SE, and Mitsubishi Kakoki Kaisha Ltd are engaged in adopting product launches, acquisitions, and product development as key developmental strategies to strengthen their position. For instance, in August 2022, SPX Flow Inc. signed a collaboration with Flottweg SE, which deals in separation technology for numerous industrial sectors. The main aim of the partnership was to improve the product portfolio of decanter centrifuges for the food and beverage sector.

Increasing demand for separation solutions for industries such as chemical processing, food & beverage, and wastewater treatment facilities, where efficient separation processes are crucial for operational efficiency and environmental compliance, is a significant driver for market growth. In addition, this equipment plays a vital role in managing large volumes of wastewater by efficiently separating solids from liquids. Also, stricter regulations across the globe to manage wastewater effectively creates the demand for such products. For instance, in October 2024, according to the source of U.S. Environmental Protection Agency (EPA), enforced regulations under the Clean Water Act, which mandates effective wastewater treatment processes, thereby surging the demand for efficient equipment for separation.

The COVID-19 pandemic had a significant impact on the global market due to supply disruption and project delays. It halted manufacturing facilities across the globe, which restricted the market growth during the forecast period. Moreover, the rising focus on decentralized production and increasing acceleration of remote monitoring and digital technologies in scroll centrifuge fueled the market growth after the COVID-19 pandemic.

IMPACT OF TECHNOLOGY

Integration of Advanced Technologies to Bolster Market Growth

An integration of technologies such as Artificial Intelligence (AI) and Internet of Things (IoT) technology in these products which enhances the efficiency and performance of separation capacity, which fuels the market growth. Moreover, the integration of advanced technologies in such products offers features such as reduced manual intervention, minimized downtime, improved operational efficiency, minimized error, and maximized productivity.

Moreover, major players engaged in the market are offering products with eco-friendly nature with the ability to recycle and separate water and oil efficiently. Also, the rising adoption of eco-friendly machines across various industry verticals, such as food processing and wastewater management applications, boosts the growth of the market. For instance, in January 2023, GN Separation Equipment Manufacturer introduced a new three-phase decanter centrifuge for oil and water separation. It has been found to be applicable in the separation of oily sludge treatment, fish products, oil clarifying, kitchen waste treatment, and wheat starch production. It is an environment-friendly machine, cost-effective, and requires less energy consumption.

Decanter Centrifuge Market Trends

Integration of Automation and IoT Enhances Operational Efficiency and Reduces Downtime

Major key players are engaged in the integration of Industry 4.0 and IoT technologies in the screw centrifuge to improve the efficiency of the machine and also maximize the production capacity of sludge treatment. With the adoption of sensors and software, modern equipment enables real-time monitoring and control of the separation process. An integration of technological advancements in decanter centrifuge allows precise control, reduced operational risks, and predictive maintenance during industrial activities. Moreover, IoT-enabled machines can offer features such as timely maintenance and minimizing downtime, improve production capacity, and reduce maintenance costs.

MARKET DYNAMICS

Market Drivers

Increasing Demand for Efficient Solid-Liquid Separation Drives Market Growth

Rising demand for solid-liquid separation equipment across wastewater treatment, chemical processing, and food & beverage fuels the decanter centrifuge market growth. Moreover, expanding wastewater treatment capacity in developing regions and rising investment in mining activities, requires energy-efficient machines for effective operations.

Globally, there are stringent government regulations for tightening wastewater discharge and Zero Liquid Discharge (ZLD) requirements in water-stressed regions. For instance, according to the source of Invest India, in October 2024, the Indian government planned to invest around USD 7,320.0 million in 30 metal and mining projects in India.

Market Restraints

High Installation and Maintenance Costs Limit Adoption of Decanter Centrifuge in Smaller Industries

High initial capital investment is required for a decanter centrifuge owing to factors such as complex installation. The advanced technology employed in these centrifuges, the quality of materials used in their construction, and the customization required to meet specific industry needs are other factors restraining the market growth.

The cost of such a machine ranges from USD 50,000 to USD 150,000 and varies for every industry. This significant upfront investment acts as a huge barrier for small and medium-sized enterprises (SMEs).

Market Opportunities

Rapid Industrialization in Emerging Economies Drives Market Expansion

The growth in industrialization and urbanization in emerging economies, such as India, Brazil, and Africa, as well as increasing investments in infrastructure and industrial activities and the surge in the demand for decanter centrifuges, fuel market growth. Moreover, these machines are used for efficient solid-liquid separation in various sectors, such as wastewater treatment, chemical processing, and food production. In Asia, the large population and increasing urbanization are driving the need for efficient wastewater treatment solutions.

Also, growth in both developing and developed regions fuels investment in infrastructure and industrial operations, driven by the adoption of decanter centrifuges for industrial separation, which enhances market growth. For instance, according to a study by the Milken Institute, around 2 billion people in Asia Pacific lack access to adequate water and sanitization programs. Also, the Asian Development Bank plans to invest around USD 200 million in water and wastewater-related services in 2025. In addition, an estimated USD 60.0 billion is required for wastewater and water-related services across Asia Pacific, which is anticipated to provide growth opportunities.

SEGMENTATION

By Product Type

Two-phase Dominates Due to Rising Demand from Chemical and Wastewater Management

Based on product type, the market is classified into two-phase and three-phase.

The two-phase centrifuges segment dominated the market in terms of revenue share of 67.23% in 2026 and is projected to grow at the highest rate during the forecast period. These products are extensively used for separating solids from liquids in industries such as wastewater treatment and oil processing, where single-phase separation suffices. Additionally, the rising expansion of key industries, such as chemical, food & beverages, and wastewater management, fuels market growth.

Three-phase centrifuges are anticipated to grow at a steady rate during the forecast period. They are used for separating two immiscible liquids and solids simultaneously, catering to applications such as oil refining and food processing.

By Design Type

Horizontal Decanter Set to Observe Substantial Growth Due to Rapid Industrialization and Expansion of Infrastructure Development

Based on design type, the market is classified into vertical decanter, horizontal decanter, and conveyor centrifuge decanter.

Horizontal decanter dominated in 2026 by holding the largest decanter centrifuge market share and is anticipated to grow at a significant rate. Rising industrialization and increasing expansion of infrastructure development across the globe fuels market growth. Also, these decanters offer versatility, efficiency, and widespread use in industries including wastewater treatment and chemical processing. The segment is expected to dominate the market share of 55.46% in 2026.

Vertical decanter is anticipated to grow at a steady rate during the forecast period, owing to its water and wastewater treatment application. Also, the rising adoption of these centrifuges in small and medium-sized operations and the rising adoption in the cosmetics and chemical industry fuel the market growth. This segment is anticipated to exhibit a CAGR of 6.40% during the forecast period.

Conveyor centrifuge decanters are anticipated to grow at a moderate rate, owing to factors such as their specialized functionality for industries needing enhanced solid-liquid separation. This segment holds a smaller market share compared to horizontal designs.

To know how our report can help streamline your business, Speak to Analyst

By Application

Water Management Dominate Market Due to Rising Investment in Water and Wastewater Plant

Based on application, the market is classified into mining and minerals, heavy oil and mineral oil, food and beverage, biofuels/agriculture processing, water management, chemical, pharmaceuticals & biotechnology, and others. The others sub-segment consists of the paper and pulps industry.

Water management applications dominated the market in terms of revenue share of 31.93% in 2026 and is projected to depict the highest growth during the forecast period. The segment’s growth is attributed to stringent environmental regulations which are driving demand for wastewater treatment solutions. These centrifuges are critical for sludge dewatering and efficient water recycling in this sector.

Mining & minerals and heavy oil & mineral oil applications are projected to grow steadily. The equipment plays an important role in the separation of solids from drilling muds and refining processes. In addition, they are essential in mining for dewatering mining slurries and separating valuable minerals from waste materials. The segment is expected to dominate the market share of 10% in 2025.

Food & beverages and biofuels/agriculture processing is projected to grow at a stable rate. This growth is driven by the factors such as the increasing demand for high-quality food products and the support for bioethanol production, which involves extracting biomass from liquids during fermentation in biofuels and agriculture processing. This segment is anticipated to exhibit a CAGR of 6.50% during the forecast period.

Chemical and pharmaceutical & biotechnology are projected to grow at a moderate rate during the forecast period. Rise in the investment in chemical and pharmaceutical plants surges demand for such products for the separation of solid and liquid chemicals and bolsters segment’s growth.

The others segment consists of paper and pulp sector and is anticipated to grow at a decent rate during the forecast period, owing to stringent government regulations aimed at reducing water pollution and waste generated from the paper and pulp industry. Also, rising demand for such machines in the paper and pulp sector, fuels the market growth.

DECANTER CENTRIFUGE MARKET REGIONAL OUTLOOK

The market covers five major regions, mainly North America, Europe, Asia Pacific, the Middle East & Africa, and South America. North America dominated the market in terms of share in 2024.

North America

North America Decanter Centrifuge Market Size, 2025 (USD Billion)

To get more information on the regional analysis of this market, Download Free sample

North America dominated the market in terms of revenue share of 34.1% in 2025, owing to factors such as increasing investment in industrial activities and stringent government regulations in the U.S., Canada, and Mexico, which drive the demand for efficient separation techniques in numerous industry verticals. The regional market value in 2026 was USD 0.81 billion, and in 2025, the market value led the region by USD 0.77 billion. Moreover, the rising adoption of decanter centrifuges in wastewater, chemical, and oil & gas sectors fuels the demand for more efficient centrifuges.

Download Free sample to learn more about this report.

U.S. to Dominate Due to Adoption of Such Products in Chemicals, Food & Beverages, and Water Management Application

The U.S. market size is estimated to hit USD 0.56 billion in 2026. A strong presence of major players such as Centrisys, Derrick Corporation, and Noxon in the U.S. market, enhances the product portfolio of separation technologies across numerous industry verticals. Moreover, the government mandates the installation of efficient solid and liquid separation units, particularly in wastewater treatment, where decanter centrifuges are essential for sludge dewatering and efficient water recycling. Furthermore, increasing focus on efficiency is facilitated by advancements in Internet of Things (IoT) and AI, and are expected to boost further the adoption of decanter centrifuges in various industries across the U.S.

To know how our report can help streamline your business, Speak to Analyst

Europe

Europe is anticipated to account for the second-highest market size of USD 0.71 billion in 2026, exhibiting the second-fastest growing CAGR of 5.66% during the forecast period. Europe is projected to grow steadily during the forecast period due to the presence of major players such as GEA Group, Flottweg SE, and Alfa Laval, contributing to its robust industrial base. Additionally, the region's commitment to environmental sustainability and renewable energy initiatives create favorable conditions for the adoption of decanter centrifuges in sectors such as wastewater treatment and chemical processing. The market value in U.K. is expected to be USD 0.12 billion in 2026. On the other hand, Germany is projecting to hit USD 0.18 billion and France is likely to hold USD 0.07 billion in 2025.

Asia Pacific

Asia Pacific region is to be anticipated as the third-largest market with USD 0.60 billion in 2026. Asia Pacific is projected to grow at a moderate rate owing to strong economic investment in industrial developments across China, Japan, South Korea, and India. Also, growth in the chemical, pharmaceutical, and petrochemical companies enhance the demand for efficient solid and liquid separation equipment. Moreover, the rising focus on improving efficiency and quality and rising investment in industrial infrastructure across China, Japan, and India bolsters market growth. The market value in China is expected to be USD 0.23 billion in 2026.

On the other hand, India is projecting to hit USD 0.08 billion and Japan is likely to hold USD 0.06 billion in 2026.

Middle East & Africa

The Middle East & Africa is projected to be fourth-largest market with a size of USD 0.15 billion in 2026 and grow at a moderate rate during the forecast period, owing to factors such as the large presence of oil and gas-producing companies across GCC, South Africa, and North Africa. An increasing adoption of three-phase decanter centrifuges across the oil and gas industry, power generation, and industrial waste treatment sectors is anticipated to boost market growth. The GCC market size is expected to be USD 0.07 billion in 2025.

South America

South America is anticipated to grow decently during the forecast period due to growth in industrial activities, especially in Brazil and Argentina, which creates the demand for decanter centrifuges for efficient solid and liquid separation technologies. In addition, increasing focus on sustainability practices and growing demand for such equipment in the mining and agricultural sectors fuel the market growth.

COMPETITIVE LANDSCAPE

KEY INDUSTRY PLAYERS

Major Players Adopt Partnership, Product Development, and Acquisition as Key Strategies to Strengthen Position

Key players such as Centrisys, Alfa Laval, Andritz AG, Derrick Corporation, TOMOE Engineering Co. Ltd, and IHI Corporation, among others, are engaged in adopting acquisition, product development, and partnership as key developmental strategies. For instance, in September 2024, GEA Group Aktiengesellschaft launched a new CF 8000 decanter centrifuge across the Europe region. It is specially designed for starch extraction application with a capacity of 15-20 tons of wheat flour per hour. It can support both two-phase and three-phase. It offers features such as an eco-friendly machine, automatic operation, and quick response time, and it ensures maximum time.

List of Key Decanter Centrifuge Companies Profiled:

- Centrisys (U.S.)

- Alfa Laval (Sweden)

- Andritz AG (Austria)

- Derrick Corporation (U.S.)

- Flottweg SE (Germany)

- FLSmidth A/S (Denmark)

- GEA Group Aktiengesellschaft (Germany)

- IHI Corporation (Japan)

- Mitsubishi Kakoki Kaisha Ltd (Japan)

- Pieralisi Maip SpA (Italy)

- TOMOE Engineering Co Ltd (Japan)

- Haus Centrifuge Technologies (Turkey)

- Noxon (U.S.)

- Elgin Separation Solutions (U.S.)

- Pennwalt (Sweden)

- Sanborn Technologies (U.S.)

- Ferrum AG (Switzerland)

KEY INDUSTRY DEVELOPMENTS:

- November 2024: GEA Group Aktiengesellschaft provided six GEA biosolids and 8000 dewatering series of decanters to the West Delta Wastewater Treatment Plant, based in Egypt. This wastewater treatment plant can process 7.5 million cubic meters of sewage sludge every day. According to the Guinness Book of Records, this is recognized as the largest wastewater treatment plant in terms of size and treatment capacity.

- November 2023: TOMOE Engineering Co., Ltd. declared that it started the process of establishing a representative office in India to carry out market research and promote the company's products in the region.

- July 2023: ANDRITZ AG developed a new three-phase decanter centrifuge designed for oil recovery in demanding industrial situations. It found application in the oil and gas industry. It offers features such as having ATEX Zone 1 and Zone 2 standards, being eco-friendly, reducing downtime, and maximizing productivity.

- May 2023: GEA announced an investment of around USD 53 million for upgrading its centrifuge manufacturing plants located in Oelde and Niederahr, Germany. Through this investment, GEA is targeting to achieve additional growth in its primary markets, which encompass the food, beverage, and pharmaceutical sectors.

- January 2022: Centrisys, a manufacturer of dewatering and thickening centrifuges, announced that its U.S. leadership successfully acquired complete ownership of the company. This acquisition brings greater stability for customers and employees.

REPORT COVERAGE

The global decanter centrifuge market research report provides a detailed analysis of the market and focuses on key aspects such as leading companies, product type, design type, application, and region. Besides, it offers insights into the market trends and highlights key industry developments. In addition to the factors above, it encompasses several factors that have contributed to the growth of the market in recent years.

Request for Customization to gain extensive market insights.

Report Scope and Segmentation

|

ATTRIBUTE |

DETAILS |

|

|

Study Period |

2021-2034 |

|

|

Base Year |

2025 |

|

|

Estimated Year |

2026 |

|

|

Forecast Period |

2026-2034 |

|

|

Historical Period |

2021-2024 |

|

|

Growth Rate |

CAGR of 6.5% from 2026 to 2034 |

|

|

Unit |

Value (USD Billion) |

|

|

Segmentation |

By Product Type

By Design Type

By Application

By Region

|

|

|

Key Market Players Profiles in the Report |

Centrisys (U.S.), Alfa Laval (Sweden), Andritz AG (Austria), Derrick Corporation (U.S.), Flottweg SE (Germany), FLSmidth A/S (Denmark), GEA Group Aktiengesellschaft (Germany), IHI Corporation (Japan), Mitsubishi Kakoki Kaisha Ltd (Japan), Pieralisi Maip SpA (Italy), and TOMOE Engineering Co Ltd (Japan) |

|

Frequently Asked Questions

As per a Fortune Business Insights study, the market was valued at USD 2.38 billion in 2026.

In 2034, the market is expected to record a valuation of USD 3.92 billion.

The market is projected to grow at a CAGR of 6.5% during the forecast period of 2026-2034.

The two-phase segment is expected to lead the market during the forecast period.

An increasing demand for efficient solid-liquid separation equipment in chemical and wastewater plants is expected to drive market growth.

Centrisys, Alfa Laval, Andritz AG, Derrick Corporation, Flottweg SE, FLSmidth A/S, GEA Group Aktiengesellschaft, IHI Corporation, Mitsubishi Kakoki Kaisha Ltd, Pieralisi Maip SpA, and TOMOE Engineering Co Ltd are the top companies in this market.

North America is projected to hold the highest market share.

Technological innovations in decanter centrifuges provide lucrative opportunities for market growth.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us