Peristaltic Pump Market Size, Share & Industry Analysis, By Type (Hose Pumps and Tube Pumps), By Application (Metering, Transfer, and Dispensing), By End-User (Medical and Pharmaceuticals, Water Treatment, Food and Beverage, Chemical Processing, and Mining and Construction), and Regional Forecast, 2025-2032

KEY MARKET INSIGHTS

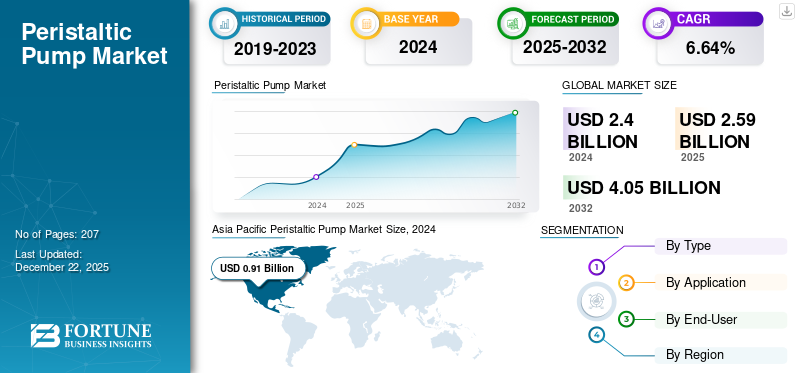

The global peristaltic pump market size was valued at USD 2.40 billion in 2024. It is projected to be worth USD 2.59 billion in 2025 and reach USD 4.05 billion by 2032, exhibiting a CAGR of 6.64% during the forecast period.

A peristaltic pump is a type of positive displacement pump that moves fluids through a flexible tube using a rolling or squeezing action. Rollers or shoes press against the tubing in a sequential motion, pushing the liquid forward while preventing backflow. Since the fluid contacts the inner surface of the tubing and not the pump’s internal parts, these pumps are particularly useful for handling sterile, corrosive, or sensitive fluids. They are commonly used in medical devices, laboratories, food processing, and chemical industries where hygiene and precision are critical.

The market is growing rapidly as these pumps address critical needs across industries requiring precise, contamination-free, and versatile fluid handling. The peristaltic pumps industry is also expanding due to advancements in pumping technologies since the pumps constitute a flexible, precise, low-maintenance and contamination-free processing of rugged and sensitive fluid found within pharmaceuticals, chemicals, food processing sector and water treatment.

With the increasing need for water and wastewater treatment, the demand for these pumps is increasing as they depend on abrasive slurries, viscous fluids, and corrosive chemicals; provide accurate chemical dosing; and have reduced maintenance requirements. Additionally, these pumps are targeting the core issues of industries including pharmaceuticals, food & beverage, chemicals, and mining. Key players in the market include Verder Group, Graco Inc., and others.

MARKET DYNAMICS

Market Drivers

Increasing Pharmaceutical and Biotechnology Industry to Drive Market Growth

The peristaltic pump market growth is majorly due to rising activities in the pharmaceutical and biotechnology industries as they provide reliable, precise, sterile, and contamination-free handling of fluids, all of which are essential during drug manufacturing, vaccine production, and biologics processing.

In February 2023, Verder Liquids launched the Verderflex Dura 80 peristaltic pump. The Dura 80 is used for various applications in the pharmaceutical and process industries. With a flow rate of 42 m³/h and a maximum differential pressure of 16 bar, it is a high-flux solution.

Market Restraints

High Initial Cost Compared to Alternatives to Restrain Market Growth

Peristaltic pumps are typically more expensive than other options, such as diaphragm, centrifugal, or gear pumps, resulting in cost-sensitive sectors being hesitant to adopt, particularly in developing economies. Many small and medium enterprises (SMEs) and municipal water treatment plants in developing economies are resource-constrained. Peristaltic pumps require a higher startup cost, which limits such users who are likely to benefit from their implementation.

Market Opportunities

Expansion of Water and Wastewater Treatment Creates an Opportunity for Market Growth

With the expansion of water and wastewater treatment, the market for peristaltic pumps is gaining higher traction, as they provide excellent chemical dosing capabilities, are suitable for abrasive and corrosive fluids, and offer low maintenance requirements, which suit major modern treatment facilities.

In May 2025, Lutz-Jesco GmbH announced the acquisition of the FXM line of peristaltic metering pumps from Valmet. This acquisition enhances Lutz-Jesco’s portfolio and solidifies its global footprint in the industrial and municipal fluid handling sectors. The FXM series, previously branded under Flowrox as a durable and rugged workhorse line for moving abrasive and viscous fluids, will be fully absorbed into Lutz-Jesco’s offering of high-quality transfer and metering equipment. This acquisition includes related technology, designs, and intellectual property, thus providing continuity and support for any current FXM customers.

Peristaltic Pump Market Trends

Increasing Adoption in Emerging Markets to Drive Market Growth

The uptake of peristaltic pumps in emerging markets is growing due to increased industrialization, urbanization, and environmental regulations. As water/wastewater treatment, pharmaceuticals, food & beverage, and mining are growing rapidly in India, Southeast Asia, GCC (Gulf Cooperation Council), and Africa, there is a strong demand for reliable, low-maintenance, effective puncture and sensitivity pumps that can handle abrasive, viscous, and harmful fluids.

Download Free sample to learn more about this report.

SEGMENTATION ANALYSIS

By Type

Capability to handle highly Viscous and Corrosive Fluids to Drive Hose Pumps Segment Growth

The market by type covers hose pumps and tube pumps.

Hose pump holds the largest peristaltic pump market share. This is due to its capability to handle highly viscous, abrasive, and aggressive fluids where traditional pumps can struggle. The segment receives wide-ranging market acceptance as mines, sewage treatment plants, and chemicals and power generation industries utilize hose pumps for reliable slurry transfer, high solid content, and precise dosing.

The tube pumps segment is the second-largest segment in the market. This is driven by increasing demand in pharmaceuticals, biotechnology, laboratories, and food & beverage, where precision, hygiene, and contamination-free handling of fluids is critical.

By Application

High Demand for Precise and Reliable Fluid Dosing in Water Treatment to Drive Segment Growth

The market is segmented by application into metering, transfer, and dispensing.

Metering is the dominating segment in the market owing to their ability to deliver accurate and consistent flow rates, even with viscous, abrasive, or chemically aggressive fluids. The flow is determined by rotor speed and tubing size, which makes calibration straightforward and repeatable. Industries such as water and wastewater treatment, pharmaceuticals, biotechnology, and chemicals rely heavily on metering for dosing chlorine, pH adjusters, enzymes, and catalysts. The main strength of peristaltic pumps in metering lies in their precision and their ability to maintain sterility, as the fluid only contacts the tubing.

The dispensing segment is the second largest segment in the market as it focuses on delivering controlled, repeatable portions of fluid rather than continuous flow. Peristaltic pumps are well-suited for this as they can be programmed to dispense exact volumes by controlling rotation cycles. They are commonly used in food and beverage processing for portioning additives, flavors, and nutritional ingredients, as well as in laboratories and medical devices for dispensing reagents, test samples, or IV solutions. The key advantage of peristaltic pumps in dispensing is their hygienic design, which ensures that sensitive or sterile fluids remain uncontaminated since they only touch the tubing. They are particularly effective in handling shear-sensitive or viscous liquids, which are challenging for piston-based dispensers.

By End-User

Rising Demand for Contamination-Free Fluid Handling in Drug and Biotech Applications Drives the Segment Growth

The market is segmented by end-user into medical and pharmaceuticals, water treatment, food and beverage, chemical processing, and mining and construction.

Medical and pharmaceuticals are the dominating segments in the market. The medical and pharmaceutical segment is taking the lead due to the fact that peristaltic pumps provide a sterile, contamination-free, and accurate way to handle fluids, all of which is required for processes such as the manufacturing of drugs, vaccines, and laboratory processes.

The chemical processing segment is the second largest segment in the peristaltic pump market. This is due to the capability of peristaltic pumps to transport corrosive, abrasive, and viscous chemicals safely and with accurate dosing, while also needing minimum maintenance, which makes them perfect for industrial chemical applications.

PERISTALTIC PUMP MARKET REGIONAL OUTLOOK

The market has been analyzed geographically BY North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa. Asia Pacific is the dominating region in the market.

North America

Asia Pacific Peristaltic Pump Market Size, 2024 (USD Billion) To get more information on the regional analysis of this market, Download Free sample

The need for effective water treatment solutions is increasing in North America due to population growth, environmental issues, and regulatory controls. Peristaltic pumps are commonly used for chemical dosing, sludge handling, and transferring abrasive fluids. It offers benefits including being self-priming and requiring low maintenance. In addition, it can transfer challenging fluids, which makes them perfect for both municipal and industrial water treatment use.

U.S.

The demand for peristaltic pumps in the U.S. is being driven by several converging factors. A major contributor is the pharmaceutical and biopharmaceutical industry, where the technology supports sterile and contamination-free transfers in single-use systems, which are increasingly adopted in biologics and vaccine manufacturing. The medical sector adds further momentum, as these pumps are integrated into infusion and dialysis equipment that benefit from their precision and safety, both critical for an aging population and rising chronic care needs. This growth is also evident in water and wastewater treatment, where stricter Environmental Protection Agency (EPA) guidelines require accurate dosing of disinfectants and coagulants, making peristaltic pumps a cost-effective option due to their resistance to chemical corrosion.

Europe

European industries have stringent regulations on hygiene, sustainability, and fluid handling. As they can operate without contamination and are able to comply with cleanroom protocol, peristaltic pumps are being embraced by the pharmaceutical, biotechnology, and food industries. The EU’s focus on eco-design and energy efficiency also adds to this trend.

Asia Pacific

The Asia Pacific region market is dominating due to rapid industrialization and urbanization, resulting in rising demand for suitable and effective fluid handling systems in industries such as pharmaceuticals, food and beverage, and water treatment. Peristaltic pumps are increasingly used in these and other back-end processes due to their high accuracy and contamination-free nature.

Latin America

Countries in Latin America are placing a large focus on investment in infrastructure projects, which include water treatment facilities, chemical processing plants, and manufacturing businesses. In these industries, peristaltic pumps are a preferred method of pumping as they can handle viscous fluids, slurries, and precise dosing. Peristaltic pumps are used for applications including water and wastewater treatment, chemicals, and food and beverage.

Middle East & Africa

The Middle East & Africa region is noticing massive investments in infrastructure such as water treatment facilities, chemical processing plants, manufacturing sectors, and others. Peristaltic pumps are preferred due to its ability to accommodate fluids with viscosity, slurries, and precise dose requirements. This makes peristaltic pumps well-suited for water & wastewater treatment, chemicals, and food & beverage applications.

COMPETITIVE LANDSCAPE

Key Market Players

Vendors Are Expanding Their Product Portfolios to Strengthen Market Presence

Leading Vendors such as Boxer GmbH, Boyser, Gilson, Netzsch Pumps & Systems, and others are expanding their product portfolios to strengthen their market positions and meet customer needs. These companies are strengthening its position in the peristaltic pump market by expanding its product offerings and aligning with industries that demand precise and reliable fluid handling. They emphasize robust designs that can handle abrasive, viscous, and chemically aggressive media, making its pumps suitable for sectors such as mining, wastewater treatment, chemicals, and food processing. By integrating advanced control technologies and focusing on durability, they also ensure reduced maintenance and higher efficiency for end users, which adds value in cost-sensitive applications.

- In November 2024, Netzsch Pumps & Systems expanded its peristaltic pump range with the introduction of the new Peripro tube pump. The Peripro pump has been designed specifically for demanding dosing applications that require continuous operation, for example, in the field of wastewater treatment. The pump is hermetically sealed, so that no medium could escape after a tube rupture, preventing contamination or possible environmental damage.

List of Key Peristaltic Pump Companies Profiled

- Watson Marlow Fluid Technology Group (U.K.)

- Verder Group (Netherlands)

- ProMinent Group (Germany)

- Cole-Parmer Instrument Company, LLC (U.S.)

- Graco Inc. (U.S.)

- Boxer GmbH (Germany)

- Randolph Austin (U.S.)

- Gilson (U.S.)

- Valmet (Finland)

- Boyser (Germany)

- NETZSCH Group (Germany)

- Heidolph Instruments (Germany)

- Wanner Engineering (U.S.)

- Longer Pump (China)

- Cole Parmer Instrument Company llc (U.S.)

KEY INDUSTRY DEVELOPMENTS

- In January 2025, QED Environmental Systems, Inc., a manufacturer of innovative environmental sampling products and a subsidiary of Graco Inc., announced the launch of the MicroPurge MP100 peristaltic pump system for low-flow groundwater purging and sampling. The MicroPurge MP100, which recently underwent a successful trial period in the U.S. and U.K., now joins their comprehensive range of groundwater sampling products.

- In June 2024, Cole-Parmer, an Antylia Scientific company, announced the offering of peristaltic pumps to round out its best-in-class line of fluid handling solutions. For the first time, Cole-Parmer is working in partnership with a U.K.-based manufacturer Watson-Marlow to offer leak-free, innovative peristaltic pumps for a wide range of laboratory, pharmaceutical, and industrial applications.

- In February 2024, NETZSCH Pumps & Systems was in the process of building a new production plant at its Brazilian manufacturer facility as part of the NETZSCH group’s global plan for manufacturing and providing the NOTOS multiple screw pumps. This new plant will take over production of all multiple screw pumps globally, which will free up capacity for the manufacture of existing NEMO progressing cavity pumps, TORNADO rotary lobe pumps, grinders, and downhole products to be manufactured at the existing plant.

- In January 2022, Longer Pump is introducing a new dPOFLEX industrial peristaltic pump tailored to meet the requirements of the biopharmaceutical and industrial market. Two casings for the pump can be a metallic stainless steel housing and a cast aluminum housing. Both pump and casing have a high IP rating (IP66) and are therefore usable in harsh environments and by sensitive applications that require aseptic conditions.

- In February 2021, ProMinent expanded the operational range of the DULCO flex Control DFXa to 65l/h to a maximum back pressure of 7 bar, thus completing the family of peristaltic dosing pumps. For small dosing quantities, the company has a specific variant available.

REPORT COVERAGE

The report provides a detailed analysis of the market. It focuses on key aspects such as leading companies, product/service processes, competitive landscape, and the leading peristaltic pump market regions. Besides, the report offers insights into the market trends and highlights key industry developments. In addition to the above factors, the report encompasses several factors that contributed to the market's growth in recent years.

Request for Customization to gain extensive market insights.

Report Scope & Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2019-2032 |

|

Base Year |

2024 |

|

Estimated Year |

2025 |

|

Forecast Period |

2025-2032 |

|

Historical Period |

2019-2023 |

|

Growth Rate |

CAGR of 6.64% from 2025 to 2032 |

|

Unit |

Value (USD Billion) |

|

Segmentation |

By Type

|

|

By Application

|

|

|

By End-User

|

|

|

By Geography

|

Frequently Asked Questions

As per the Fortune Business Insights study, the market size was USD 2.40 billion in 2024.

In 2024, the Asia Pacific market value stood at USD 0.91 billion.

The market is expected to exhibit a CAGR of 6.64% during the forecast period of 2025-2032.

The Medical & Pharmaceuticals segment led the market by end-user.

Increasing demand from Pharmaceutical and Biotechnology Industry to drive market growth.

Some of the top major players in the market are Boxer GmbH, Boyser, Gilson, and others.

Asia Pacific dominated the market in 2024.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us